Air-Tightness Testing

Pulse Air Permeability Testing

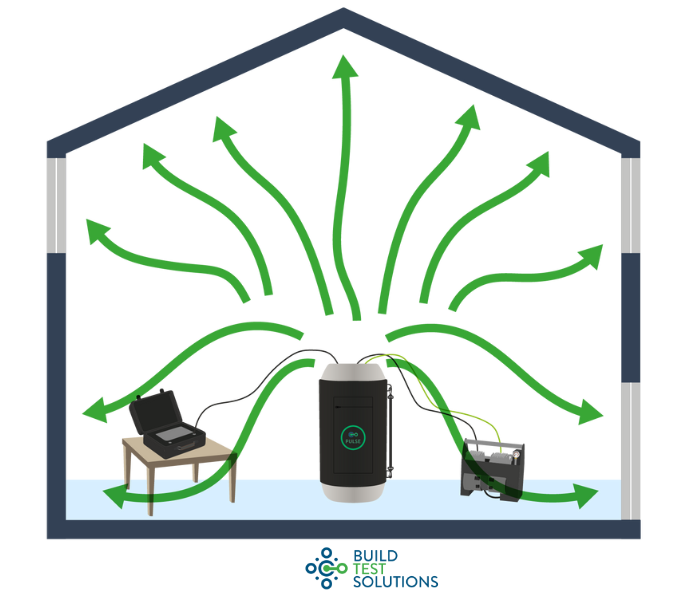

Pulse air permeability testing is a test that measures the

air-tightness of buildings. The test takes place during actual operation of the building and is performed without any disruption to the building’s occupants.

Air change rate measurement is one component of this type of testing. It measures how much air is exchanged in a building over time and can help determine whether a building requires additional ventilation to reduce carbon dioxide levels or to maintain comfort conditions.

Air change rate measurement is one component of this type of testing. It measures how much air is exchanged in a building over time and can help determine whether a building requires additional ventilation to reduce carbon dioxide levels or to maintain comfort conditions.

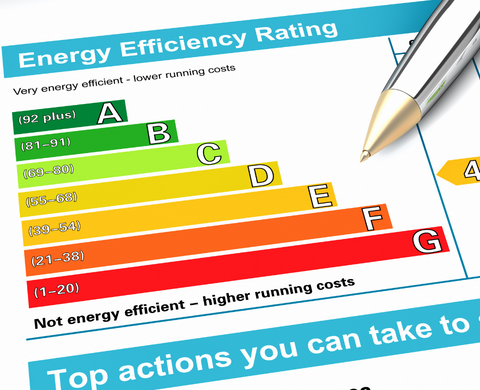

Make your Energy efficiency ratings more

accurate.

Part L of the building regulations requires all domestic new builds to be tested using an approved air pressure testing method. The Pulse air-tightness measurement system is approved under both Part L and PAS 2035 retrofit standard.

Step 1

We will explain the full process, give you a quote and arrange for one of our Pulse technicians to attend the property at a convenient day and time.

Step 2

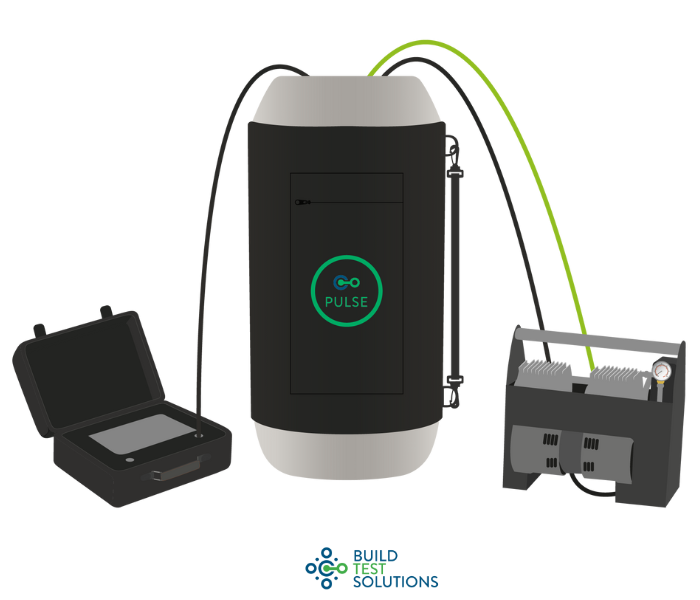

Our Technician will attend the property, explain the process to the occupier & set up the Pulse air receiver (usually on the ground floor of the property being tested).

Step 3

The Pulse test will be launched by the technician using the touch-screen control unit. This will release one or more “pulses” of air into the internal space of the building creating a pressure difference between inside and outside.

Step 4

The Technician will upload the data for a report to be produced. The report includes all information about the test and the property it was performed on. You will then receive the report as a PDF via email.

Air Leakage Detection & Diagnostics

Achieving an airtight building fabric, minimising uncontrolled losses and putting in place an appropriate and controllable ventilation strategy is well understood as being a pragmatic means of achieving good energy efficiency levels as well as a comfortable and healthy indoor environment.

The Leak Checker Diagnostics Fan generates a significant pressure differential that enables the detection of air leakage pathways. These pathways can be identified by either tactile means, such as feeling them with your hand, or by using advanced visualization tools, such as a smoke pen or thermal imaging camera. This approach provides a reliable and effective means of pinpointing and diagnosing air leaks in a building.

Make your Energy efficiency ratings more accurate.

Air tightness tests are carried out after the construction of the building and meeting the required standard with the test result satisfies compliance with Part L of the building regulations in England & Wales and regional variants in Scotland and Northern Ireland.

Step 1

Our technician will fix the sealing within an open window, exposing one side to the inside of a house and the other side to the external air. Clamps will be used to ensure a good seal around the sheet so that the fan can generate a pressure difference between inside and outside.

Step 2

Next the Technician will attach the the mounting rail within the window frame or recess to provide support for the fan. The Leak Checker fan will be attached and a well-sealed barrier is created. Internal/external pressure sensor tubes are then connected.

Step 3

Once powered on the fan will allow our Technician to detect air leakage paths by feeling for noticeable draughts around the room or using a smoke pen. A thermal camera may also be used to identify leakage paths around fixtures and fittings.

Step 4

The diagnostic data will be compiled into a report which will include all information about the test and the property it was performed on. You will then receive the report as a PDF via email allowing you to seal the identified air leakage paths.